Intelligent control system of gas ovenBack

Product introduction :

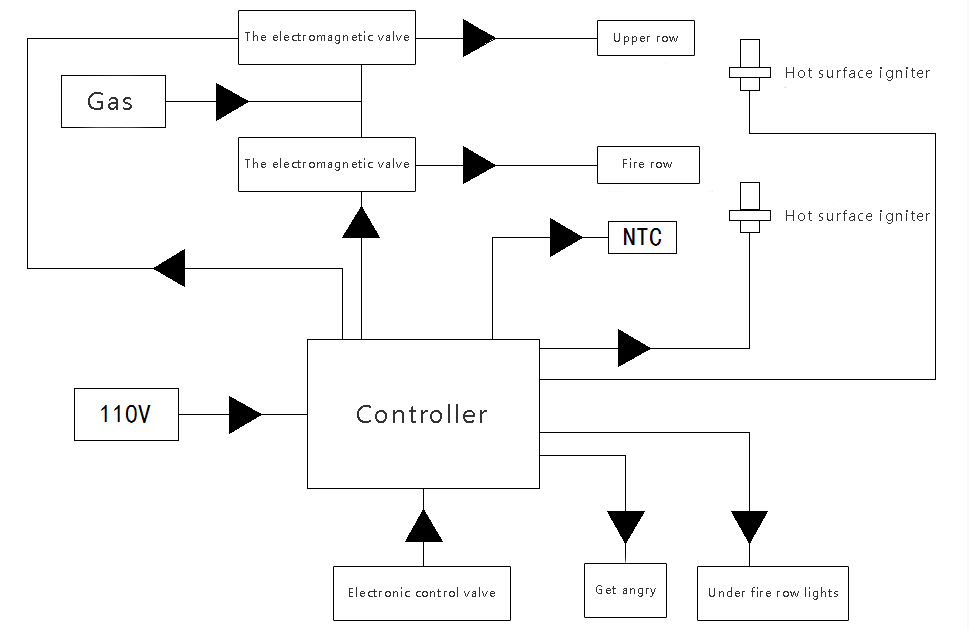

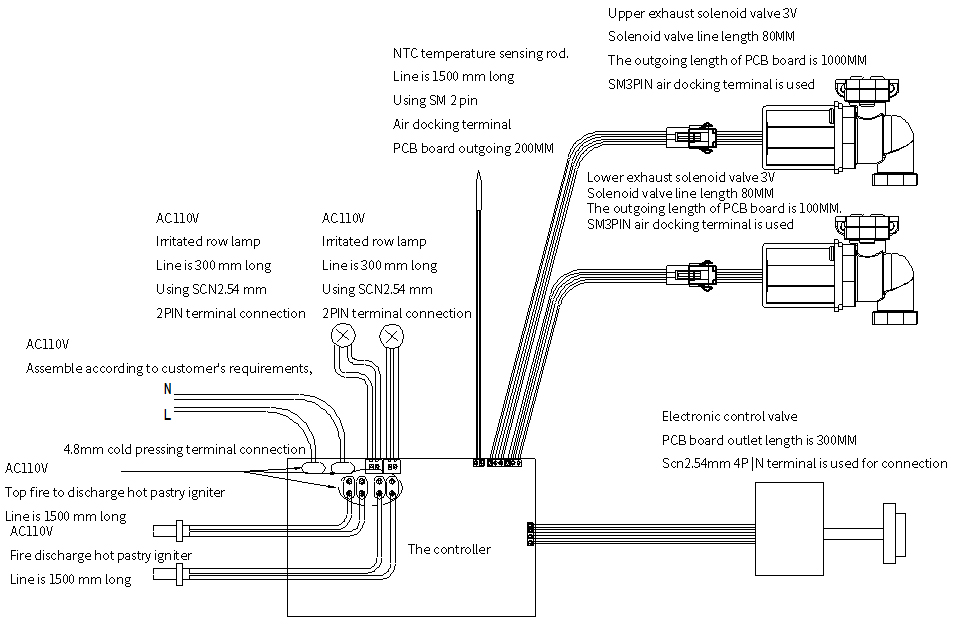

1. The temperature control accuracy is higher than the traditional liquid expansion temperature control system, which can reach within ± 8 ℃, and the temperature control range is 50 ~ 260 ℃ (according to customer requirements)

2. The operation and use method is the same as the traditional liquid expansion temperature control system, and the installation method is also the same.

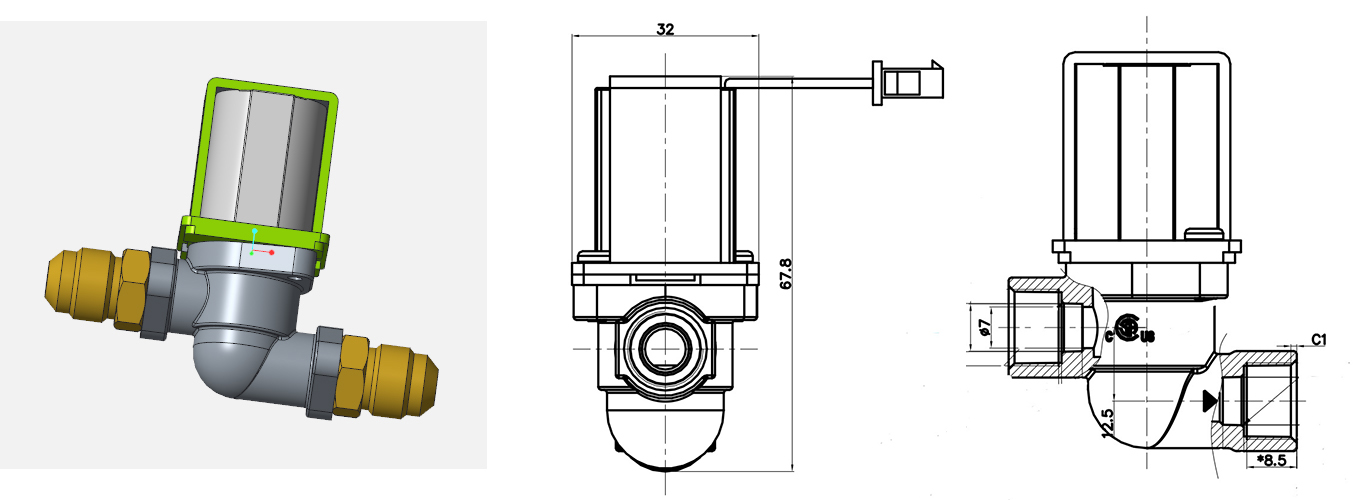

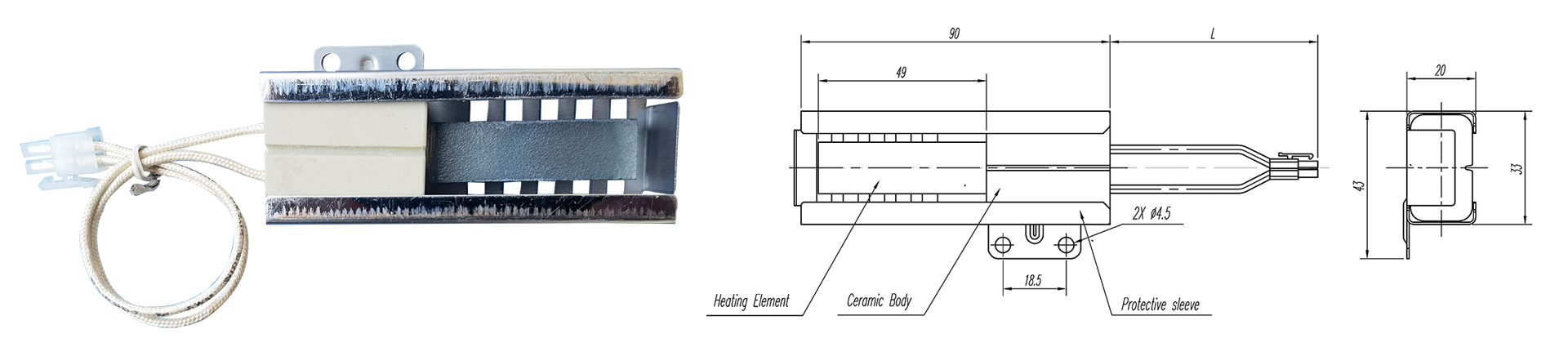

3. Can be used with safer silicon nitride hot surface igniter

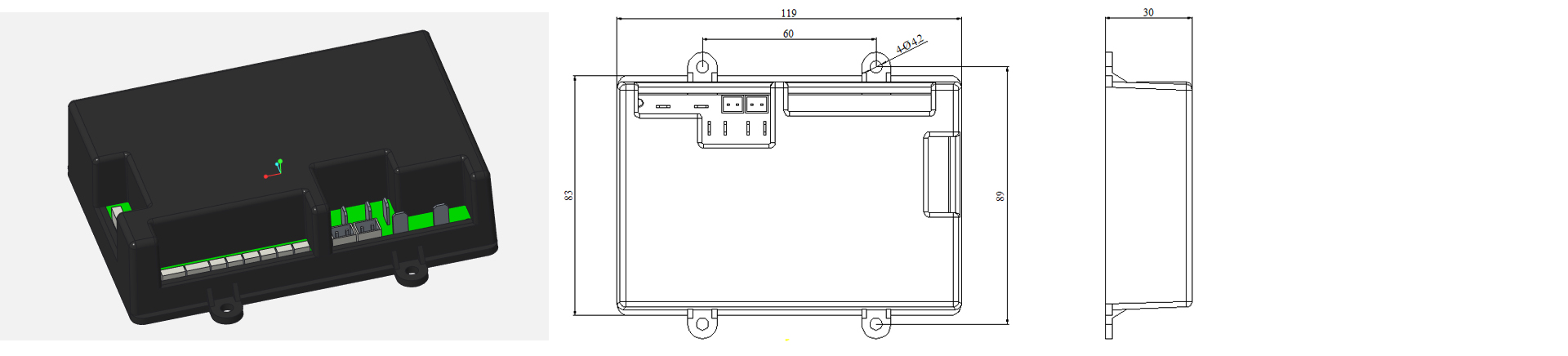

4. The service life of the electronic temperature control valve is 300,000 times

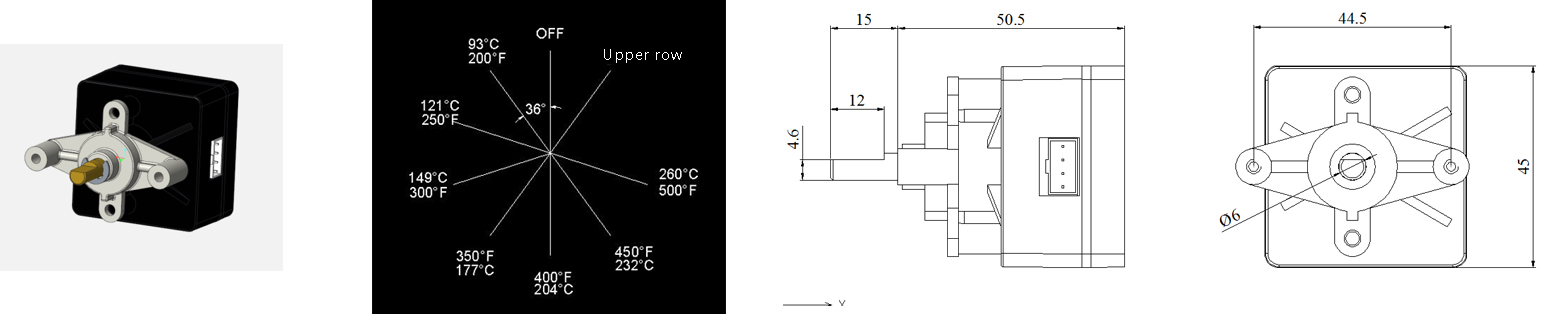

5. The life of the electronic control selection valve is 10000 times

1. The temperature control accuracy is higher than the traditional liquid expansion temperature control system, which can reach within ± 8 ℃, and the temperature control range is 50 ~ 260 ℃ (according to customer requirements)

2. The operation and use method is the same as the traditional liquid expansion temperature control system, and the installation method is also the same.

3. Can be used with safer silicon nitride hot surface igniter

4. The service life of the electronic temperature control valve is 300,000 times

5. The life of the electronic control selection valve is 10000 times

Home

Home

Business one

Business one Business two

Business two